Cast Iron Grit

Price 68 INR/ Kilograms

Cast Iron Grit Specification

- Material Composition %

- Fe 94-97%, C 2.0-3.5%, Si 1.0-3.0%, Mn 0.3-1.0%, Cr 0.05-0.5%

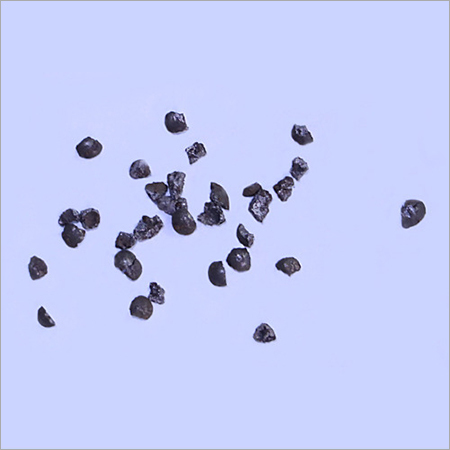

- Diameter

- Available from 0.2 mm to 3.0 mm (depends on grade)

- Coating Type

- Uncoated

- Corrosion Resistant

- Moderate, depends on application

- Hardness

- 45-60 HRC (410-650 HV)

- Tensile Strength

- Not applicable (brittle material)

- Recyclable

- Yes, multiple uses depending on application

- Product Form

- Granular Grit

- Heat Resistance

- Yes

- Size

- G10, G18, G25, G40, G50 (various sizes as per requirement)

- Product Name

- Cast Iron Grit

- Steel Type

- Cast Iron

- Steel Product Type

- Abrasive Grit

- Grade

- G10, G18, G25, G40, G50 (other sizes possible)

- Thickness

- NA (granular product, thickness determined by grit size)

- Shape

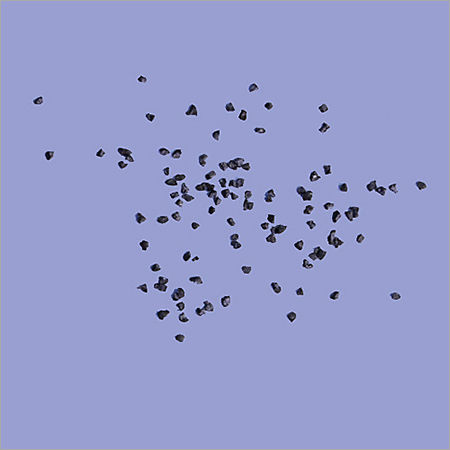

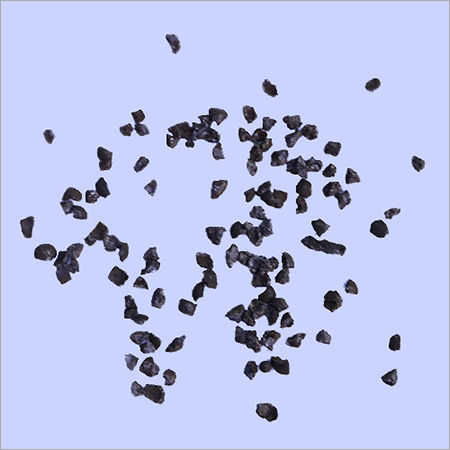

- Angular, Grit

- Steel Standard

- IS 4606, DIN 8201, SAE J444 / J827

- Surface

- Rough, angular

- Composition

- Cast iron (mainly Fe, C, Si, Mn, Cr)

- Application

- Abrasive blasting, surface preparation, cleaning, descaling, stone cutting, and etching

- Dimension (L*W*H)

- NA (available in various grit sizes)

- Weight

- Varies as per packaging, typically 25 kg or 50 kg bags

- Color

- Dark grey to black

- Material Grade

- Standard foundry cast iron grade

- Finish Type

- Natural Cast

- Usage

- Surface cleaning, rust removal, sand removal, granite and marble cutting

- Delivery Condition

- Dry and free-flowing

- Bulk Density

- 4.0 - 4.5 g/cm³

- Melting Point

- Approximately 1200°C

- Packing Type

- Polypropylene bags, jumbo bags, drums

- Standard Packaging Size

- 25 kg or 50 kg bags, 1 ton jumbo bags

- Particle Shape

- Angular, irregular

- Shelf Life

- Unlimited under dry storage conditions

- Specific Gravity

- 6.8 - 7.2 g/cm³

- Non-toxic

- Yes

Cast Iron Grit Trade Information

- Minimum Order Quantity

- 250 Kilograms

- Payment Terms

- Cheque

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 3 Months

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- pp bags

- Main Domestic Market

- All India

About Cast Iron Grit

Cast Iron Grit manufactured by us is known to be of excellent quality and assures superior performance. It is used for blasting applications to prepare any surface for spray painting & welding. This iron grit offers superior cleaning & roughening properties and shows compatibility for descaling purpose as well. It is used in automotive, foundries, steel fabricating, & aviation industries. Cast Iron Grit has optimum surface hardness with sharp & angular structure.

Features:

- Ensures fast cleaning

- Reusable & recyclable in nature

- Good structural strength

High-Quality Abrasive for Demanding Applications

Cast Iron Grit delivers consistent results in abrasive blasting, surface preparation, and stone cutting. Its angular, hard granules rapidly remove rust, scale, and other contaminants, ensuring clean, profiled surfaces. The product is versatile, suitable for granite, marble, metals, and more.

Durable and Eco-Friendly Solution

Designed with a long service life and unlimited shelf life under dry conditions, Cast Iron Grit can be reused multiple times depending on the application. Its composition (mostly Fe, C, Si, Mn, Cr) ensures reliability while being non-toxic and recyclable, making it an environmentally conscious abrasive choice.

FAQs of Cast Iron Grit:

Q: How should Cast Iron Grit be stored to maintain its quality?

A: Cast Iron Grit should be stored in dry conditions to preserve its dry and free-flowing delivery state. Properly sealed polypropylene bags, drums, or jumbo bags are ideal to prevent moisture uptake, ensuring the grits performance remains consistent over time.Q: What is the main process involved in using Cast Iron Grit for surface preparation?

A: The primary process involves abrasive blasting, where Cast Iron Grit is propelled at high velocity onto surfaces to clean, descale, or etch. Its angular structure provides strong impact, making surface cleaning, rust removal, and preparation highly effective.Q: When is Cast Iron Grit preferred over other abrasive materials?

A: Cast Iron Grit is favored when moderate corrosion resistance, sharp angular cutting action, and recyclability are required. Its versatility suits tasks like granite cutting, metal cleaning, and surface profiling where efficient material removal is essential.Q: Where is Cast Iron Grit commonly applied?

A: It is extensively used in manufacturing facilities, foundries, shipyards, and stone processing plants across India. Typical applications include grit blasting, steel descaling, granite and marble cutting, and restoration projects.Q: What are the benefits of using Cast Iron Grit in abrasive blasting?

A: Benefits include efficient removal of contaminants due to its angular shape, increased surface profilation, high recyclability, moderate corrosion resistance, and suitability for a wide range of grit sizes and packing options.Q: Can Cast Iron Grit be recycled after use?

A: Yes, Cast Iron Grit is recyclable and can be reused multiple times, depending on the application and contamination level during use. This feature reduces waste and provides long-term cost advantages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Grits Category

G24 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Diameter : Nominal 0.71 mm (as per G24 spec)

Material Grade : G24

Surface : Grey, angular

Product Name : Other, G24 Cast Iron Grit

Industrial Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Diameter : 0.2 mm 3.0 mm (as per grade)

Material Grade : Industrial Grade

Surface : Rough, granular

Product Name : Other, Industrial Cast Iron Grit

G39 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Diameter : Approximately 0.9 1.2 mm (for G39)

Material Grade : G39

Surface : Rough/Angular

Product Name : Other, G39 Cast Iron Grit

"We are accepting local inquiries mostly from Maharashtra, Goa, Tamil Nadu, Gujarat, Karnataka"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS