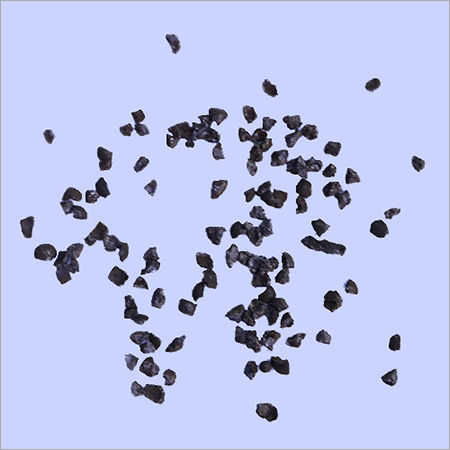

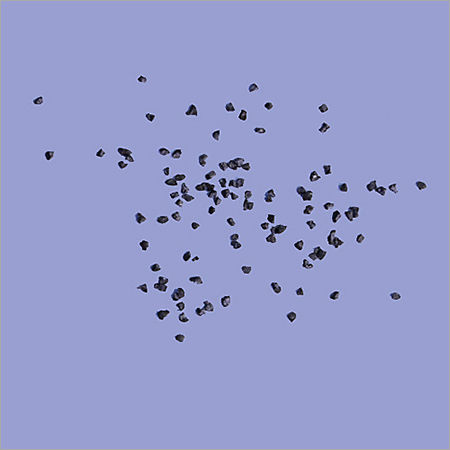

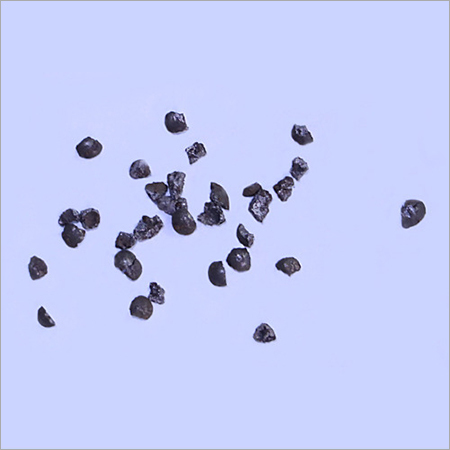

G39 Cast Iron Grit

Price 68 INR/ Kilograms

G39 Cast Iron Grit Specification

- Product Form

- Granules/Particles

- Diameter

- Approximately 0.9 - 1.2 mm (for G39)

- Material Composition %

- Carbon: 2.5-3.5%, Silicon: 0.7-2.0%, Manganese: 0.35-1.0%, Sulfur: <0.1%, Phosphorus: <0.1%

- Size

- G39 specific size grit, approx. 0.9 - 1.2 mm

- Corrosion Resistant

- No, requires dry storage

- Recyclable

- Yes, can be reused multiple times

- Hardness

- Greater than 60 HRc (Rockwell Hardness)

- Heat Resistance

- Yes

- Product Name

- G39 Cast Iron Grit

- Steel Type

- Cast Iron

- Steel Product Type

- Abrasive Grit

- Grade

- G39

- Shape

- Angular Grit

- Steel Standard

- IS 4606, SAE J444, or as per customer specification

- Surface

- Rough/Angular

- Composition

- High Carbon Cast Iron

- Application

- Surface preparation, cleaning, descaling, and shot blasting of steel surfaces

- Weight

- Depends on packaging, typically 25kg or 50kg bags

- Color

- Dark Grey to Black

- Material Grade

- G39

- Finish Type

- Matte/Rough

- Usage

- Sandblasting, surface cleaning, removal of mill scale and paint

- Max Operating Temperature

- 600°C

- Dust Formation

- Low, due to angular and hard granule structure

- Manufacturer Certification

- ISO 9001 Certified

- Packing Type

- PP bags with inner polythene lining, jumbo bags available

- Sieve Analysis

- As per G39 grade/grit size

- Bulk Density

- 4.3 - 4.6 g/cm³

- Delivery Condition

- Ready to use grit, packed and sealed

- Life Cycle

- Approximately 4-5 cycles depending on application and material condition

- Melting Point

- Approx. 1200°C

- Storage Condition

- Store in a dry, covered area to prevent moisture absorption

G39 Cast Iron Grit Trade Information

- Minimum Order Quantity

- 250 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- pp bags

- Main Domestic Market

- All India

About G39 Cast Iron Grit

Consistent Performance for Demanding Applications

G39 Cast Iron Grits hardness and angular granule structure enable aggressive yet controlled abrasion, maximizing efficiency in sandblasting and surface preparation tasks. Its reliable grit size (0.91.2 mm) and strict adherence to G39 standards guarantee consistent results for industrial cleaning and finishing operations on steel substrates.

Safe Handling and Storage Recommendations

To maintain optimal performance and prevent premature corrosion, G39 Cast Iron Grit should be stored in a dry, covered area. Each batch is sealed in PP bags with inner polythene lining or supplied in jumbo bags, ensuring durability and protection from moisture during transportation and storage.

Sustainability through Recyclability

G39 Cast Iron Grit stands out for its recyclable nature, allowing users to reuse the product for approximately 45 blasting cycles, depending on application and material conditions. This feature reduces waste and operational costs while promoting environmentally responsible industrial practices.

FAQs of G39 Cast Iron Grit:

Q: How should G39 Cast Iron Grit be stored to maintain quality?

A: G39 Cast Iron Grit should be stored in a dry, covered location to avoid moisture absorption, as it is not inherently corrosion-resistant. Using the original sealed PP or jumbo bags with inner polythene lining helps maintain its condition until use.Q: What is the typical application process for G39 Cast Iron Grit?

A: The grit is commonly used in abrasive blasting equipment for cleaning, descaling, surface preparation, and removing mill scale or paint from steel surfaces. Ensure the correct grit size and blasting parameters are set according to the specific requirements of your surface treatment process.Q: When should I replace or recycle G39 Cast Iron Grit during use?

A: G39 Cast Iron Grit can be recycled and reused typically for 45 operational cycles, though this may vary based on application, surface, and material condition. Replace the grit once it loses its angularity or effectiveness during blasting.Q: Where can I purchase G39 Cast Iron Grit in India?

A: G39 Cast Iron Grit is readily available through authorized distributors, importers, manufacturers, suppliers, traders, and wholesalers across India. Look for ISO 9001 certified suppliers to ensure product quality and authenticity.Q: What are the main benefits of using G39 Cast Iron Grit for surface preparation?

A: Its angular shape and high hardness provide aggressive abrasive action with minimal dust formation. This results in effective cleaning and surface profiling, enhancing the bond for subsequent coatings or finishes and reducing overall processing time.Q: How does G39 Cast Iron Grit comply with industry standards?

A: G39 Cast Iron Grit is manufactured to meet IS 4606 and SAE J444 standards or as per customer specification, ensuring consistent grit size, hardness above 60 HRc, and reliable physical and chemical properties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Grits Category

G24 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Shape : Other, Angular/Granular

Material Composition % : Carbon 2.03.5%, Silicon 1.22.0%, Rest Iron

Dimension (L*W*H) : As per requirement, granular/pellet structure

Tensile Strength : n/a (brittle material)

Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Shape : Other, Angular, Grit

Material Composition % : Fe 9497%, C 2.03.5%, Si 1.03.0%, Mn 0.31.0%, Cr 0.050.5%

Dimension (L*W*H) : NA (available in various grit sizes)

Tensile Strength : Not applicable (brittle material)

Industrial Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Shape : Other, Angular / Grit

Material Composition % : Fe 90% min, C 24%

Dimension (L*W*H) : Variable, as per requirement

Tensile Strength : N/A (brittle, not for load bearing)

"We are accepting local inquiries mostly from Maharashtra, Goa, Tamil Nadu, Gujarat, Karnataka"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS