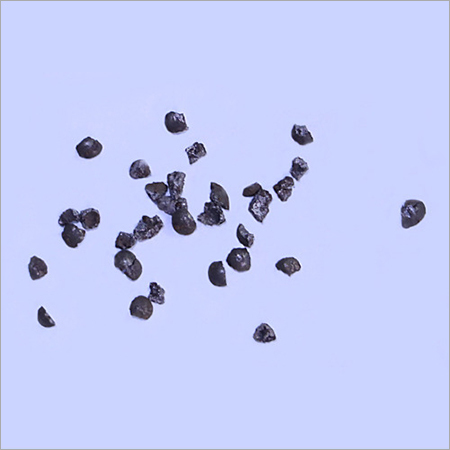

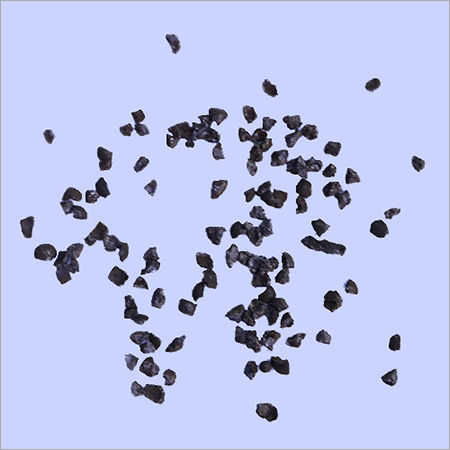

G24 Cast Iron Grit

Price 68 INR/ Kilograms

G24 Cast Iron Grit Specification

- Heat Resistance

- Yes

- Hardness

- 4065 HRC (375850 HV)

- Tensile Strength

- n/a (brittle material)

- Corrosion Resistant

- Moderate

- Diameter

- Nominal 0.71 mm (as per G24 spec)

- Material Composition %

- Carbon 2.03.5%, Silicon 1.22.0%, Rest Iron

- Product Form

- Grit

- Coating Type

- Uncoated

- Recyclable

- Yes, up to 6 cycles

- Size

- G24 (approx. 0.71 mm grain size)

- Product Name

- G24 Cast Iron Grit

- Steel Type

- Cast Iron

- Steel Product Type

- Grit/Granular abrasives

- Grade

- G24

- Thickness

- n/a (granular)

- Shape

- Angular/Granular

- Steel Standard

- IS 9162/ISO 11124-7

- Surface

- Grey, angular

- Composition

- High carbon cast iron

- Application

- Surface preparation for metal, stone, and concrete; blasting for cleaning, etching, and surface profiling

- Dimension (L*W*H)

- As per requirement, granular/pellet structure

- Weight

- Bulk supply in 25 kg, 50 kg, or 1000 kg jumbo bags

- Color

- Grey

- Material Grade

- G24

- Finish Type

- Matte/Angular

- Usage

- Abrasive blasting, cleaning, shot peening, surface preparation

- Packing Type

- HDPE / Woven jumbo bags with poly liner

- Storage Instructions

- Store in dry place, away from moisture

- Conductivity

- Non-conductive

- Shelf Life

- Indefinite if stored properly

- Maximum Operating Pressure

- Up to 8 bar in blasting machines

- MOQ (Minimum Order Quantity)

- 1 ton

- Magnetic Property

- Magnetic

- Bulk Density

- 4.04.6 g/cm

- Environmental Safety

- Free from free silica, non-toxic

G24 Cast Iron Grit Trade Information

- Minimum Order Quantity

- 250 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- pp bags

- Main Domestic Market

- All India

About G24 Cast Iron Grit

G24 Cast Iron Grit offered by us is made by melting CI and then atomizing & grain crushing. It is most commonly utilized for grit blasting purposes so as to remove rust, paint, or scale from a surface and to prepare one before welding. This grit is of very high quality and assures complete reliability. It is greatly admired for having excellent cleaning and roughening properties. G24 Cast Iron Grit can be availed at highly competitive rates in bulk as demanded by our trusted clients.

Features:

- Reusable in nature

- High structural strength

- Optimum surface hardness

Superior Surface Preparation

G24 Cast Iron Grits angular, high-carbon structure ensures robust cleaning and precise surface profiling for metal, stone, and concrete. Its hardness (4065 HRC) and non-conductive nature allow for consistent etching, making it a top choice across industries for abrasive blasting, surface cleaning, and shot peening.

Safe, Reliable, and Eco-Friendly

Manufactured to exclude hazardous free silica and toxic elements, G24 Cast Iron Grit is non-toxic, dust-limiting, and safe for operational environments. Its indefinite shelf life, when stored correctly, and recyclability (up to 6 cycles) contribute to lower waste and operational cost-effectiveness.

Versatile Packing and Application

Available in multiple packaging options25 kg, 50 kg, or 1000 kg jumbo bagsthis grit accommodates diverse project sizes. Bulk supply options and an MOQ of 1 ton ensure flexibility for distributors, wholesalers, and manufacturers across India and beyond.

FAQs of G24 Cast Iron Grit:

Q: How should G24 Cast Iron Grit be stored for maximum longevity?

A: To maintain its integrity and performance, G24 Cast Iron Grit should be stored in a dry place away from moisture. When properly stored in sealed bags or containers, its shelf life is indefinite.Q: What is the primary application process for G24 Cast Iron Grit in surface preparation?

A: G24 Cast Iron Grit is used in abrasive blasting machines, operating at pressures up to 8 bar. The process involves projecting the grit onto metal, stone, or concrete surfaces to clean, etch, or prepare them for coating or further treatment.Q: When is it beneficial to select G24 Cast Iron Grit over other abrasives?

A: G24 Cast Iron Grit is especially beneficial when aggressive surface cleaning or profiling is required, such as removing rust, scale, or coatings from hard substrates. It is particularly suitable where silica-free, non-toxic media are required for environmental safety.Q: Where can G24 Cast Iron Grit be sourced in India?

A: G24 Cast Iron Grit is available countrywide through a network of distributors, importers, manufacturers, suppliers, traders, and wholesalers. It can be ordered in bulk quantities with a minimum order of 1 ton.Q: What makes G24 Cast Iron Grit an environmentally friendly choice for abrasive blasting?

A: The grit is free from free silica and other toxic substances, ensuring minimal environmental impact and safer working conditions. Additionally, its ability to be recycled up to six times further reduces waste.Q: How does the recycling process work with this grit?

A: After abrasive blasting, the spent grit can be collected, cleaned, and reused for up to six cycles, ensuring cost efficiency and sustainable use without significant loss in abrasive performance.Q: What benefits does G24 Cast Iron Grit offer regarding operational safety?

A: G24 Cast Iron Grits non-conductive and non-toxic composition reduces operational hazards. Its dust-limiting characteristics and absence of free silica contribute to a safer, healthier blasting environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Grits Category

Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Hardness : 4560 HRC (410650 HV)

Heat Resistance : Yes

Composition : Cast iron (mainly Fe, C, Si, Mn, Cr)

Steel Standard : Other, IS 4606, DIN 8201, SAE J444 / J827

Industrial Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Hardness : Mohs 67, 4060 HRC (approx.)

Heat Resistance : Yes

Composition : Cast iron, predominantly iron with carbon and silicon

Steel Standard : Other, IS 4606 / Equivalent

G39 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Hardness : Greater than 60 HRc (Rockwell Hardness)

Heat Resistance : Yes

Composition : High Carbon Cast Iron

Steel Standard : Other, IS 4606, SAE J444, or as per customer specification

"We are accepting local inquiries mostly from Maharashtra, Goa, Tamil Nadu, Gujarat, Karnataka"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS