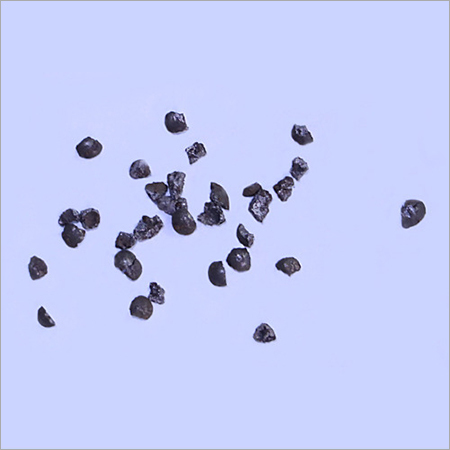

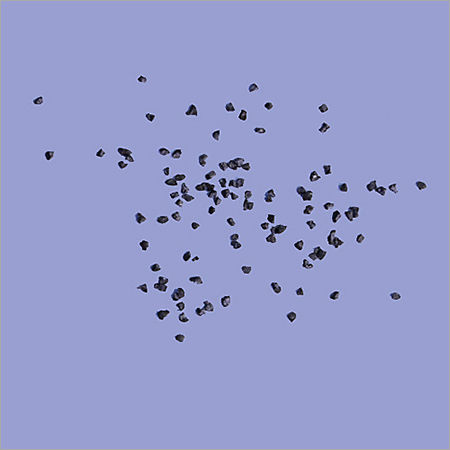

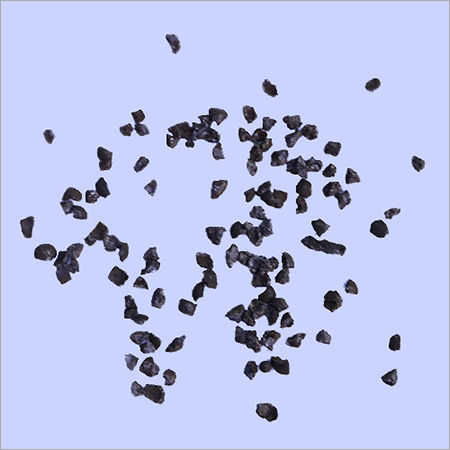

Industrial Cast Iron Grit

Price 68 INR/ Kilograms

MOQ : 250 Kilograms

Industrial Cast Iron Grit Specification

- Diameter

- 0.2 mm - 3.0 mm (as per grade)

- Corrosion Resistant

- Moderate

- Recyclable

- Yes

- Hardness

- Mohs 6-7, 40-60 HRC (approx.)

- Product Form

- Granular / Grit

- Material Composition %

- Fe 90% min, C 2-4%

- Tensile Strength

- N/A (brittle, not for load bearing)

- Size

- Customizable, as required

- Heat Resistance

- Yes

- Product Name

- Industrial Cast Iron Grit

- Steel Type

- Cast Iron

- Steel Product Type

- Grit

- Grade

- Standard Industrial

- Thickness

- N/A (Granular/Grit form)

- Shape

- Angular / Grit

- Steel Standard

- IS 4606 / Equivalent

- Surface

- Rough, granular

- Composition

- Cast iron, predominantly iron with carbon and silicon

- Application

- Abrasive blasting, surface preparation, cleaning of metal surfaces

- Dimension (L*W*H)

- Variable, as per requirement

- Weight

- Variable

- Color

- Dark grey / Black

- Material Grade

- Industrial Grade

- Finish Type

- Unpolished, natural cast

- Usage

- Blasting, deburring, etching, surface cleaning

- Bulk Density

- 4.2-4.6 g/cm³

- Melting Point

- 1200-1300°C

- Impurities

- Low sulphur and phosphorus

- Packaging Type

- HDPE bags / bulk

- Grain Size Range

- G10 - G80

Industrial Cast Iron Grit Trade Information

- Minimum Order Quantity

- 250 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- pp bags

- Main Domestic Market

- All India

About Industrial Cast Iron Grit

Industrial Cast Iron Grit is made from molten steel through an atomization process. Made from steel scrap, it is available in different sizes and hardness. It is mainly produced by crushing specifically heated hot pellets. Our offered product is prepared by our experts using high grade iron and latest technology in accordance with the market standards. Offered Industrial Cast Iron Grit is widely recognized among customers due to their long shelf life, rust resistance, high strength and cost effectiveness.

Precision Blasting for Metal Surfaces

Industrial Cast Iron Grit is engineered for abrasive blasting applications, ensuring thorough cleaning, etching, and surface preparation of metallic structures. Its angular grains provide superior impact, making it ideal for removing tough contaminants and preparing surfaces for coatings or welding in manufacturing and maintenance industries.

Consistent Quality and Composition

Produced from premium cast iron, this grit meets industrial grade standards with over 90% iron content, 2-4% carbon, and minor silicon. Low sulphur and phosphorus levels reduce the risk of contamination during use, supporting consistent abrasive performance across all batches.

FAQs of Industrial Cast Iron Grit:

Q: How is Industrial Cast Iron Grit used in surface preparation?

A: Industrial Cast Iron Grit is primarily utilized in abrasive blasting, where it is propelled at high velocity against metal surfaces to remove rust, paint, scale, or other contaminants, ensuring clean surface profiles suitable for further treatment or coating.Q: What are the main benefits of using cast iron grit over other abrasives?

A: Cast iron grit offers high hardness and angular characteristics, providing quick and effective cleaning while ensuring excellent surface profile. Its recyclability and low level of impurities also make it a cost-effective and environmentally responsible choice.Q: When should I choose Industrial Cast Iron Grit for my application?

A: Use Industrial Cast Iron Grit when you require aggressive surface cleaning, etching, or descaling of steel and cast iron components, especially for preparation prior to painting or coating, or when removing stubborn residues from heavily corroded metal surfaces.Q: What packaging and sizes are available for Industrial Cast Iron Grit?

A: This product is offered in HDPE bags or bulk packaging, with customizable grain sizes (G10 - G80; 0.2 mm - 3.0 mm) and quantities designed to suit various industrial blasting machines and operational needs.Q: Where is Industrial Cast Iron Grit typically applied?

A: It is widely used in industries such as shipbuilding, construction, automotive, and metal fabrication for tasks like tank cleaning, structural steel preparation, and foundry floor maintenance, wherever robust abrasive cleaning is required.Q: What processes does cast iron grit undergo during manufacturing?

A: Cast iron grit is manufactured by melting high-quality cast iron, forming it into granular shapes, and then sizing it into precise grades while ensuring minimal sulphur and phosphorus content for optimal abrasive properties.Q: Is cast iron grit recyclable and how does this benefit my operation?

A: Yes, cast iron grit is recyclable and can be reused multiple times within blasting operations, offering significant cost savings and reducing environmental impact compared to single-use abrasives.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cast Iron Grits Category

G24 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Color : Grey

Diameter : Nominal 0.71 mm (as per G24 spec)

Shape : Other, Angular/Granular

Finish Type : Matte/Angular

Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Color : Dark grey to black

Diameter : Available from 0.2 mm to 3.0 mm (depends on grade)

Shape : Other, Angular, Grit

Finish Type : Natural Cast

G39 Cast Iron Grit

Price 68 INR / Kilograms

Minimum Order Quantity : 250 Kilograms

Color : Dark Grey to Black

Diameter : Approximately 0.9 1.2 mm (for G39)

Shape : Other, Angular Grit

Finish Type : Matte/Rough

"We are accepting local inquiries mostly from Maharashtra, Goa, Tamil Nadu, Gujarat, Karnataka"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS